Case Study II - Bourges Green Waste Treatment Plan

TerraWatt

Securing domestic production of cost-effective bio-methane (SEMPRE-BIO) is a project helping build Europe’s Green Deal and a solid circular economy. Yet, security of energy supply in Europe remains one of the most challenging tasks of the 2030 Agenda. Considering this important environmental feat, innovation technology has been presented as part of Europe’s compromise in building and achieving a de-carbonized economy.

To be able to move forward with innovation technology solutions, SEMPRE-BIO, supports entities and projects that are providing environmentally friendly and interdisciplinary expert knowledge solutions. Such is the case of TerraWatt, participating in one of the three European Biomethane Innovation Ecosystem (EBIEs) projects supported by SEMPRE-BIO.

TerraWatt, founded by Yann Mercier, is a French start-up based in Paris, France. The company was established in 2014, mainly focusing on sustainable solutions. Aside from the focus on sustainability, its founder, patented the transformation of organic material into methane, hydrogen, and carbon dioxide, using thermochemical and biological processes.

The patent was a milestone that led to an interesting solution opportunity to take place in a nearby city of Bourges (Marmagne). Today, TerraWatt is taking the lead in building a small-scale green waste-to-biomethane plant, complementing its development via Case Study II – Bourges Green Waste Treatment Plan (CS II), which will monitor and track significant advances of the plant. Additionally, Case Study II takes a key role in the process that is being conducted regarding the production of biomethane from green waste.

Case Study-II, Bourges Green Waste Treatment Plant

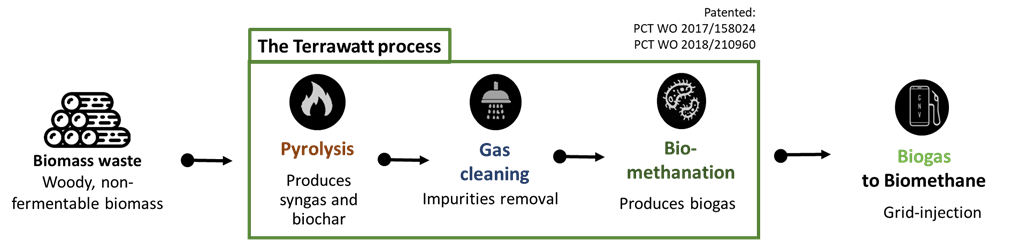

TerraWatt’s technology which has been patented since 2018, follows a process and pyro-methanation patent, consisting of the innovative combination of thermochemical processes as pyrolysis and biological process, which converts syngas into biogas. This is unique as it is a developing technology which has never been implemented at a pilot scale.

Terrawatt’s unit takes place in Marmagne’s ecopole, which already has an AD plant, a solar panel farm and a waste treatment platform. This innovative place wants to nurture new projects and efforts that can help fight climate change. Additionally, green wastes coming from the city of Bourges, will be used as feedstocks taking part of Case Study II – Bourges Green Waste Treatment Plan, for continuous analysis and optimization of the syngas bio-methanation process.

Pyro-Methanation Plant

To understand the level of granularity of this process, the pyro-methanation unit consists of a high temperature pyrolysis combined with bio-reactors, converting biomass into biogas following a two-step process.

The biogas obtained by methanation, will be upgraded to biomethane through the existing AD plant facilities and injected into the gas grid. This will demonstrate the technology, becoming relevant for the environment and setting the basis for a commercial technology. CS II will also analyze the use of non-fermentable and non-recyclable waste as feedstock for biomethane production, key to Europe’s future and domestic energy supply.

Understanding Terrawatt’s Process

In more detailed steps, the graphic above explains TerraWatt’s process:

- Woody biomass is collected from the green waste of Bourges. The non-fermentable fraction is isolated and shredded.

- The biomass goes through a pyrolysis unit at high temperature. This thermochemical process converts any carbonaceous feedstock to synthetic gas called syngas. Syngas is composed of Hydrogen, carbon monoxide and carbon dioxide.

- Before methanation takes place, syngas needs to undergo a purification process to get rid of impurities (tars, oils). After this phase, clean syngas can then be injected into bio-methanation reactors.

- Carbon monoxide, carbon dioxide and hydrogen from syngas will be converted into methane and carbon dioxide, under the action of a bacterial consortium, resulting in biogas.

- To supply renewable gas, the biomethane produced will be injected into the grid.

Also, Case Study II will be involved in the consistent tracking and reporting about this breakthrough technology, producing biomethane from a non-fermentable feedstock. This will showcase an example of greenfield installation, where the input is a woody biomass and not a fermentable biomass, which is the common approach for biogas production (AD Plant). Moreover, pyrogasification is part of a competitive field for both local and regional market, with both catalytic and biological methanation.

Additionally, TerraWat is working in collaboration with the Technical University of Denmark – DTU, which are prominent in developing reactors. TerraWatt’s is focused on defeating climate change by producing renewable energy through this process mentioned above. Also, pyrolysis of biomass produces a solid phase, rich of carbon, known as biochar, which can be used as bio soil amendment, participating in carbon capture mitigation.

Next Steps: Upon the commission of energy valorisation module, TerraWatt plans to sell biogas/biomethane and have diversified units in different sectors. For a long-term vision, TerraWatt includes diversifying the processes of feedstocks, to increase the level of waste valorisation and have a wider impact on climate change mitigation actions. An innovative potential remains in coupling TerraWatt’s process to AD plant to increase biogas production yield and maximize wastes valorisation (fermentable and non-fermentable wastes). TerraWatt is bringing in all its team knowledge and technical capacities to the forefront, hand in hand with SEMPRE-BIO, advancing together towards a greener and more sustainable future.

Authors: Marie André, Pierre-Yves Mocaër,

Editorial: María Francisca Paz y Miño

Date: September, 2023

This project has received funding from the European Union’s HORIZON-CL5-2021-D3-03-16 program under grant agreement No 101084297. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Commission. Neither the European Union nor the granting authority can be held responsible for them.